Concrete Floor Grinding, Staining, and Sealing-Milwaukee

Economical Two Step Grinding Service with Staining & Sealing CONTACT US OR GET A QUOTETwo Step Concrete Floor Grinding with Staining & Sealing Service in Milwaukee, in Wisconsin, and in Northern Illinois

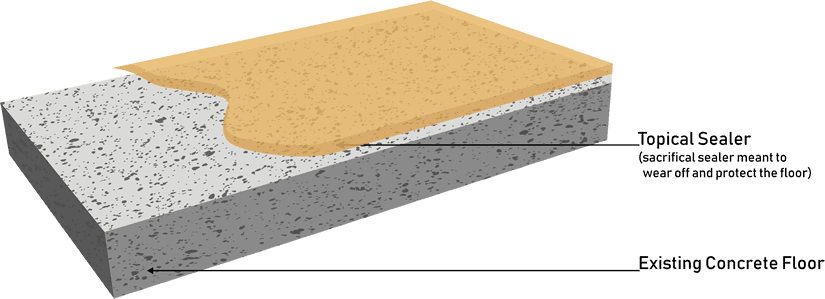

Concrete grinding, staining, and sealing concrete in Milwaukee and in Wisconsin is an economic alternative to our 10 step mechanical polish service. Grinding and sealing is also a longer term floor coating when compared to topical polish.

With grinding and sealing, the floor is “cleaned” using our commercial diamond grinding equipment. The grinding removes old coatings and dirt on the surface. The grinding prepares the surface for proper adhesion of the coatings, and the preparation is why our coatings last on floors for many, many years.

Grinding the concrete will also make the surface very flat and uniform.

Our full mechanical concrete polish leaves a high gloss, almost mirror like finish while this 2 step grinding process will leave the concrete floor surface with a nice clean, matte looking finish with very consistent small swirl scratches adding a nice look to the overall finish. Once the grinding is complete, we can add a concrete stain to the surface for a great look to what would otherwise be plain concrete.

Generally we use a water based stain that has a uniform finish that can range from transparent to opaque. Once the stain is applied, we then add our ultra durable sealer.

Where to Use Floor Grinding and Sealing Services

The grind and seal option is very popular in a number of commercial and industrial applications such as manufacturing, warehousing, retail, and food service. It is inexpensive enough that sometimes tenants of commercial or warehouse spaces that need a great looking floor that is serviceable choose this option so they don’t sink a ton of money into a floor that a landlord still owns.

Are you a Milwaukee business that needs grinding and sealing? It is a great option if you are looking for a good looking, clear, easily maintained floor with moderate life expectancy. The life expectancy can be extended with different types of sealers.

We generally apply water-based sealers but solvent-based acrylics are available as well. You will find the solvent-based sealer will tend to darken the color of the stain, but the water-based sealer will only slightly change the finished color making water-based sealers a great choice if you want a lighter floor color. The solvent-based sealer has greater durability, but there needs to be proper ventilation when applying a solvent-based sealer. If good ventilation that is not an option than the water-based sealer is the best choice.

See photo below for the finish difference between the right side with the water-based sealer and the left with the solvent-based sealer. See standard stain colors here.

Same gray color on both sides but right side is a water-based sealer, left side is solvent-based sealer.

Why Consider Grinding, Staining & Sealing Concrete Floors?

PRO’s

- Looks Great

- Fast (24-48 hours return to service)

- Easy to maintain

- Low Cost

CON’s

- Small swirls / scratches

- Small pits / holes (these were in the

concrete slab but often become more

noticable when grinding the floor and in

this system, we generally don’t repair

them unlike the full mechanical polish)

Service Time

The size of the area determines how long this process will take but generally speaking we can return the area back to service in 24 – 48 hours.

Our Process for Grinding, Staining & Sealing Floors

The grind, stain and seal process is much faster than the full mechanical polish. We begin by grinding the surface with our industrial diamond grinder until enough of the top layer is removed for good adhesion of the sealer. The idea is that we are removing the “ugly” surface, leaving a new, clean one ready to accept the stain and sealer.

We then have a number of options for sealers depending on the location and wear of the floor. If you choose to stain it, we would then apply the stain and a seal coat. Check our available colors online!

As we mentioned above, the lack of refining the floor with greater number of diamonds often will result in visible uniform swirls being the trade-off for the savings.

Contact us for a free consultation today